Introduction

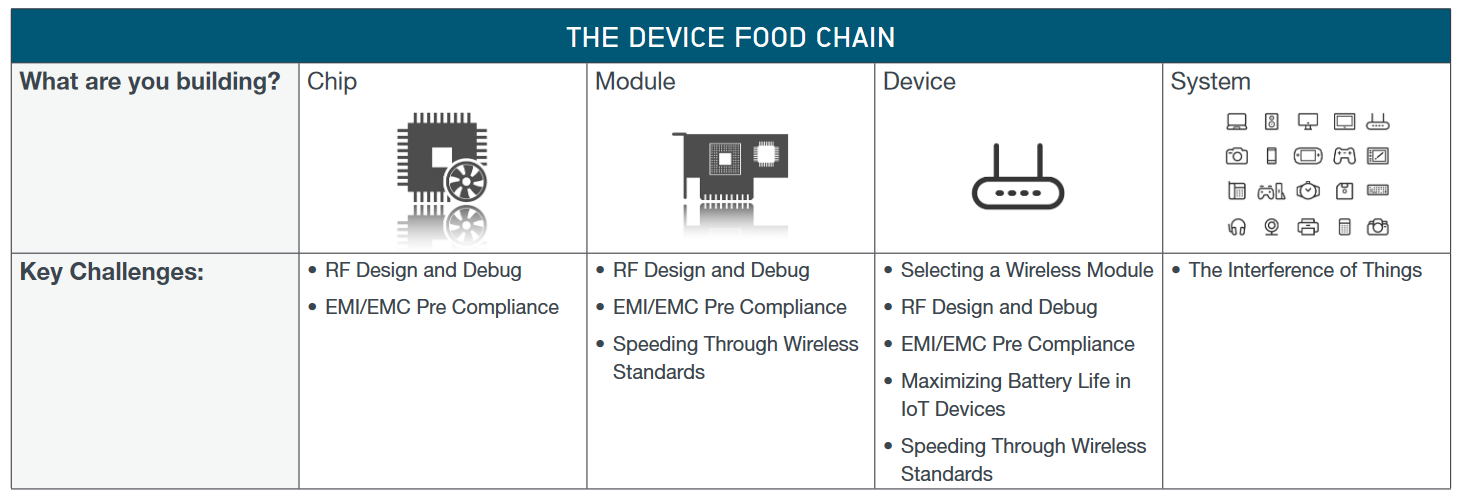

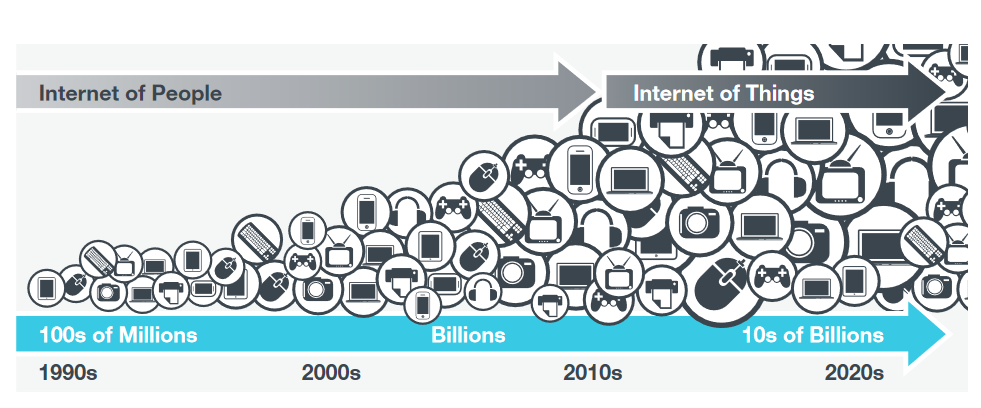

The Internet of Things (IoT) promises to change the world by connecting devices in larger, more interoperable systems controlled by software and analytics. The proliferation of device, software, and analytics will drive significant changes in most industries, from shipping and transportation to construction and manufacturing. They will even change the way we maintain our own health and fitness.

The opportunities to reinvent existing objects into connected devices that include sensors and transmitters are abundant. However, these opportunities are accompanied by technical challenges. How do we make tools and machines that have not changed in form or function for decades into electronic devices that are smart, connected, and compliant? Further, how do we ensure that the devices we design in the lab are able to perform in the field?

CHALLENGE 1

SELECTING THE RIGHT WIRELESS MODULE

When adding wireless connectivity to your products there are a number of technologies to choose from, including Wi-Fi®, Bluetooth®, ZigBee®. You may opt to buy a wireless module rather than build your own custom RF design to save time and money. However there are dozens of modules out there, and several factors to consider.

Choosing the wrong module could delay product development, so getting the right module the first time is critical. Some factors to consider are:

- Cost / Develop versus Buy decision

- Security

- Wireless technology and protocol

- Data throughput, Latency, connection setup speed

- Network topology

- Power consumption

- Real Estate

- Pre-certified or Non-pre-certified module selection

- Future-proof & Long term availability

- Robustness

- Interchangeability

- Vendor's application industry vertical focus, global presence, quality manufacturing, and support operations

- Regulatory and Industry standards compliance/qualifications requirements

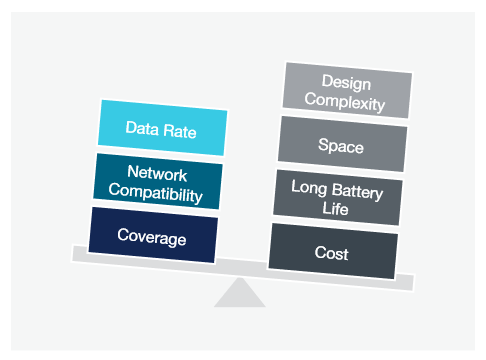

4 Common Wireless Module Trade-Offs

No one wants to compromise on the design features that matter most, so it is important to balance trade-offs well. Here are four of the most common trade-offs and what they can mean for your design.

- Module vs Reference Design

- Data Rate vs Range vs Power Requirements

- Robustness vs Interchangeability

- Cost vs Everything

CHALLENGE 2

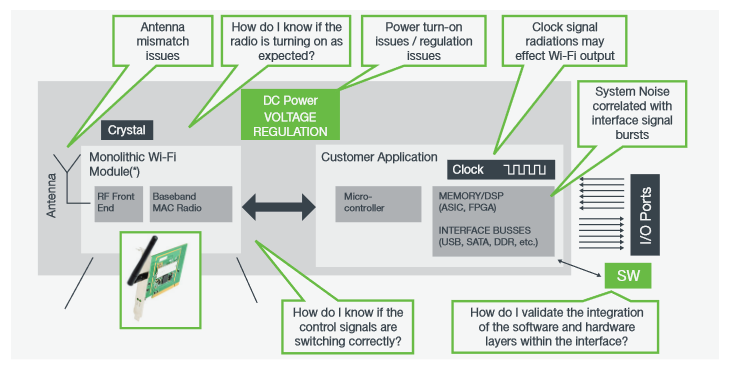

DESIGNING AND DEBUGGING COMPLEX MIXED SIGNAL DEVICES (ANALOG, DIGITAL, AND RF)

Traditionally, radio devices for most applications would have been designed by highly experienced RF design engineers. Now there are countless radio "modules" that can be purchased and integrated into your project with reference designs. These modules are helping to fuel the huge boom in IoT devices and can speed along development time. However, when it comes time to system level troubleshooting, design teams struggle to figure out if the problem lies with their module or with their device.

Trying to debug complex systems can be time consuming and costly without the right equipment and a test plan.

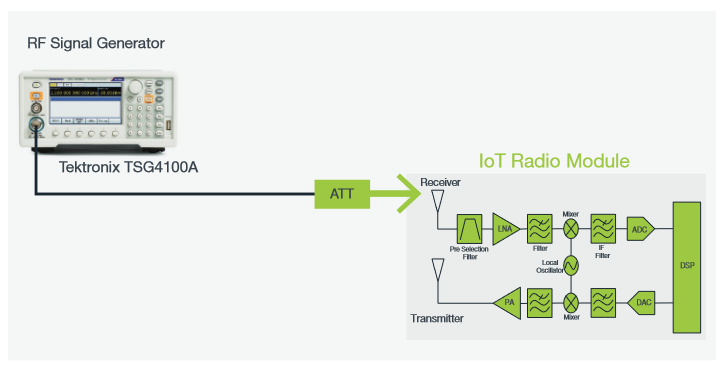

The simplest way to test if your device is transmitting a signal is to use a Spectrum Analyser to visualize the RF signal. Measuring the signal's frequency and power level are easy when using the correct instruments. If you need to test how well that your radio receiver is working, sensitivity and blocking tests are your best bet. The sensitivity test is used to verify that the receiver is capable of operating with a minimum discernible signals. A receiver blocking test is the opposite in that it verifies that the device is capable of ignoring unwanted signals while still demodulating a desired signals. Each of these tests requires an RF Signal generator.

Accelerate your design with comprehensive solutions for debugging complex Digital, Analog and RF system problems

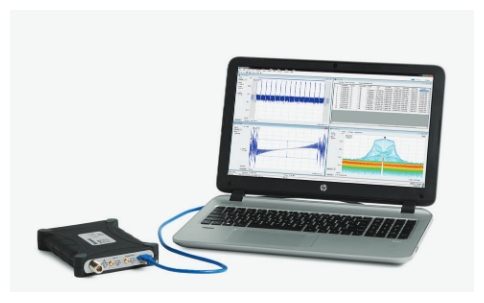

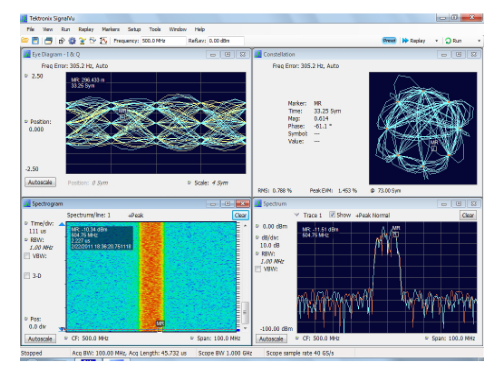

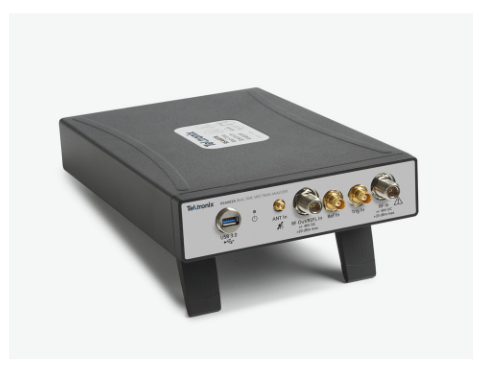

RSA306B USB Spectrum Analyzer and Signal-Vu PC

Ensure that your IoT device is transmitting at the correct power level and frequency.

TSG4100A RF Vector Signal Generator

Perform powerful functional and sensitivity tests on RF Receivers.

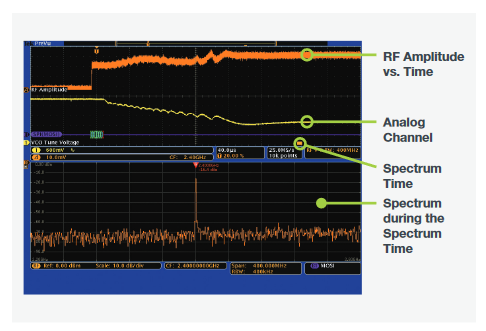

MDO4000B Mixed Domain Oscilloscope

Verify system level operation through correlation of correlating analog and digital signals with RF.

CHALLENGE 3

MAXIMIZING BATTERY LIFE

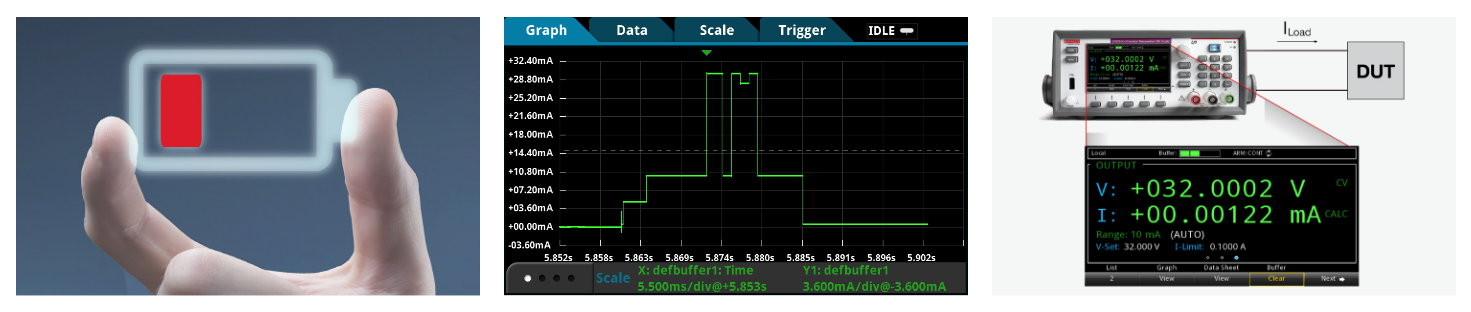

Power management is a primary concern in IoT design. The battery life of IoT devices varies greatly, from hours to years, depending on the application and its operating environment. In all cases, however, the ability to accurately describe the device's power consumption is essential. Robust power analysis helps designers identify opportunities to reduce energy consumed and optimize battery life.

10 Power Analysis Measurement Challenges

A typical IoT device contains at least one sensor, a processor, and a radio chip that operates in different states and consumes currents from tens of nA to hundreds of mA in a matter of tens of microseconds. As a result, it is important to remember these challenges when choosing equipment to perform the analysis with.

- Measuring a wide dynamic range of current levels

- Determining ultra-low deep sleep current

- Measuring transmit and receive current

- Capturing short transients and fast transitions

- Ensuring sufficient measurement bandwidth for your sample rate

- Triggering to isolate specific events

- Recording device operations over extended states

- Analyzing power consumption from complex waveforms

- Isolating device design issues from power source issues

- Providing a stable voltage for all device operating conditions

Maximize your mobile to mobile device’s battery life

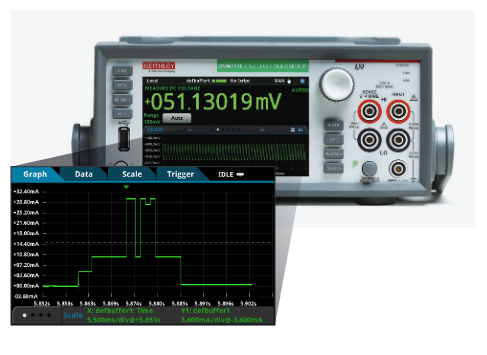

Accurately measure your IoT and M2M device’s current draw and power consumption in active, standby and sleep modes.

- Capture the current draw in all the operating states of the IoT device with the DMM7510's pA sensitivity for low sleep mode currents, 1Msample/s digitizer for transmit mode current bursts, and 27.5 million memory for acquiring a typical current profile.

- Battery Simulator offers low noise output like the 2280S Power Supply along with battery modeling and simulation.

- The 2281S Power Supply offers the same great features of the 2280S DC Power supply with additional battery modeling and simulation functionality

- When a constant voltage is desired for testing an IoT device, the 2280S Precision Power Supply has the accuracy and resolution to provide a low noise voltage source for eliminating the changing characteristics of a battery or a battery simulator.

- The 2281S Power Supply is essential when creating stable low noise voltage supply for every state of your IoT device, from sleep to transmit. Record and generate battery sources with its Battery Simulator option.

CHALLENGE 4

PASSING EMI AND EMC CERTIFICATION

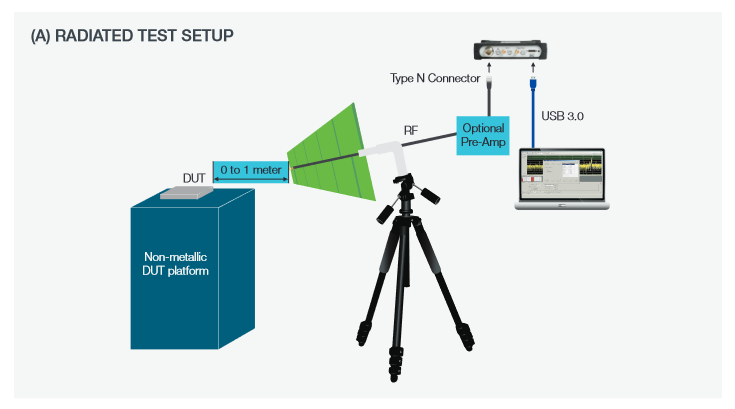

The race to add products to the Internet of Things brings a degree of complexity to EMI testing. Not only do product manufacturers need to learn how to properly add a wireless capability to their product, but from an EMI perspective it requires additional intentional radiator testing.EMI regulations are in place throughout the world to provide improved reliability and safety for users of electrical and electronic equipment.

Compliance testing is exhaustive and time consuming, and a failure in EMI in the final stages of product development can cause expensive re-design and delay time to market. In addition, the full compliance test in a certificated lab can be expensive, with costs ranging from $1,000 to $3,000 per day.

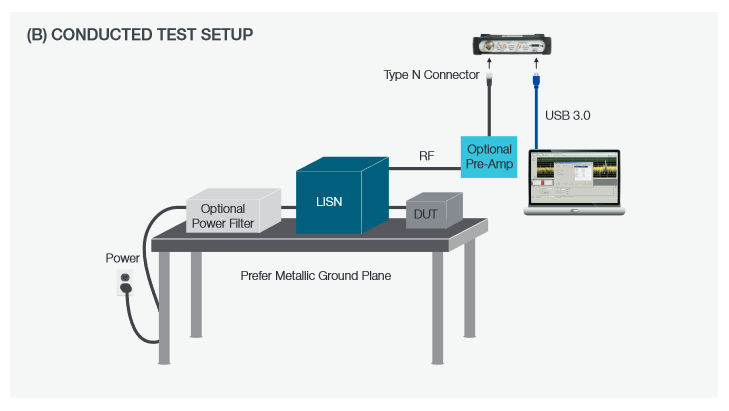

Pre-compliance testing is commonly used to catch compliance problems early and greatly improve the probability of a successful first pass of full EMI compliance testing, thus effectively reducing your time-to-market. The test set up is relatively simple and, with the right equipment and planning, can be a valuable tool in troubleshooting your design.

Periodicity and Coincidence

Are you seeking out the problem source or antenna at the heart of your EMI problem? Examining the Periodicity and the Coincidence of the signals can give you the clues to track it down.

Periodicity:

Analyzing the nature of the RF signal can help narrow down a list of possible sources. What is the RF frequency of the signal? Is it pulsed or continuous?

Coincidence:

Examining what signals occur or change simultaneously can help point to trigger events.What signal on the DUT coincides with the EMI event?

Our EMI Solution

Don't Let EMI/EMC Compliance Certification Slow You Down

Tektronix USB Spectrum Analyzers and SignalVu-PC

Faster EMC Pre-compliance without having to wait for access to a lab

- Low cost & PC-based real time spectrum analyzer

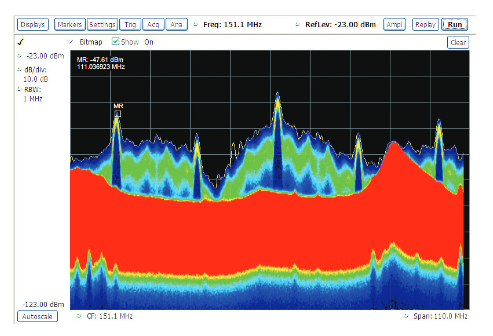

- Faster detection of short duration EMI signals with RSA306B DPX real-time technology and automated pre-compliance setups

- Built in RF record/playback to easily capture and analyze EMI spectral events

Avoid EMI caused by intentional RF transmitters

- Understand change in EMI signature due to intentional RF transmission

- Correlate EMI events with RF transmission with using RSA306B on Spectrum Emission Mask and DPX

MDO4000B Mixed Domain Oscilloscope

Faster EMI Debugging and Troubleshooting

- With MDO4000B's time correlation capability you pin point the noise source and avoid the painful and repetitive task of changing components.

- Understand the root cause analog and/or digital signals that are causing the EMI noise.

CHALLENGE 5

STANDARDS CERTIFICATION

Wireless technology standards are needed to ensure that products can interoperate within the ecosystem where they will be deployed. There are a number of technologies to choose from, including Wi-Fi®, Bluetooth®, ZigBee®. However to adhere to the standard, new products will need to meet qualification as defined per the standard selected. Failing qualification can mean design turns that will delay the final product release and draw additional significant development cost.

Pre-testing for standard qualification is a cost-effective way to catch problems early, while there is time to correct issues without costly redesigns, delays, and retesting at the test house.

What does Standard Qualification mean?

Qualification is the term used to describe what tests a product is required to pass to meet a wireless standard. Qualification ensures the product will interoperate with other devices using the same wireless standard.

Bluetooth Fast Facts

- Bluetooth SIG defines the process for granting the Bluetooth Logo to products.

- Modules can also be qualified BTE products, but do not automatically qualify the device.

- Reference design or Bluetooth profile changes need to be qualified with additional testing.

WiFi Fast Facts

- To use the "Wi-Fi Certified" logo on products, firms must become members of the Wi-Fi Alliance.

- Members submit their products for testing at Wi-Fi Alliance's designated certification testing facilities.

- The tests ensure the product meets specifications defined by the IEEE 802.11 standard committee.

Our Wireless Standards Solution

Get to market faster with compliance tests on RF transceivers with:

Signal-Vu PC Software

- Free base version of the powerful signal analysis software includes 17 measurements

- Add on over 30 options including vector signal analysis, pulsed signal analysis, and commercial wireless signal analysis.

- One user interface powers RF analysis on all Tektronix instrumentation from our USB spectrum analyzers to our most advanced oscilloscopes.

RSA600 USB Spectrum Analyzer

- Automatic standard signal detection

- Bluetooth Low Energy and Basic Rate pre-certification

- WLAN 802.11 pre-certification

- Basic Rate and Enhanced Data Rate

- Digital modulation analysis for RFID, ZigBee

- Powerful and automated measurements

- EVM, SEM, frequency error, symbol clock error

- Displays for key modulation and RF measurements

MDO4000C Mixed Domain Oscilloscope.

- Integrated triggered acquisition system - over 125 trigger combinations in the time AND frequency domains

- 20 Mpoint record length with Wave Inspector® controls

- True spectrum analyzer hardware enables real spectrum analysis

- Expandable functionality ensures usefulness well into the future

CHALLENGE 6

COMBATTING THE INTERFERENCE OF THINGS™

Over the past decade there has been a dramatic increase in the population of wireless transmitters found in the world. Arguably the spectrum in the 2.4 GHz is the most popular operating area for low-cost, license free applications and there are literally millions of radios operating in this frequency band. Utilizing license exempt spectrum is attractive because of the cost savings, but you get NO protection from all the other people using the same channels.

Cellular Network Operators employ teams who specialize in identifying and eliminating interference to maintain network quality. However, interference poses a unique challenge to device manufacturers as well. Engineers are finding that even when they use a "certified" solution, they are still having problems establishing a radio link and maintaining communications in the field. Diagnosing these problems with a real-time spectrum will help you characterize what's happeng to your device in the prescence of all the other devices using the same spectrum.

What is Interference Hunting?

Interference hunting is the art/science of finding sources of RF interference within a network area and neutralizing its effects.

Interference hunting has become common practice with network providers. This trend is driven by a greater number of wireless network users expect high quality and reliable access.

Quick resolution of network issues requires fieldready tools that allow interference hunters to observe the RF spectrum in real time.

How To Troubleshoot A Radio Link

- Characterize the Radio Link - Draw a picture of what "good" looks like using the radio specifications.

- Analyze the Radio Link in Real Time - View the signal in real time to look for anomalies.

- Characterize the RF Environment - See the complete picture by seeing how the signal interacts with others in its environment.

Now that you can see the problem, you can get on with fixing it.

Combatting Interference

Interference Hunting made fast, easy and inexpensive for M2M connectivity in Factory Automation/ Industrial Process Control and Spectrum Management.

Field Friendly for Interference Hunters, Network Installers, and Maintenance

- Compact size and low weight - fits easily in your backpack and easy to carry around in the field

- Ruggedized Mil-Std PRF-28800F Class 2 to operate in harsh conditions

- Battery powered with 4 hours of run time

- Collaborate with HQ sharing field data recorded on your Windows tablet

Fast interference hunting and spectrum compliance made easy

- Quickly discover co-channel interference and transients with DPX

- Easily classify interference with signal classification and LTE BTS-ID

- Keep up with changes in spectrum allocation and new interferers with an open, customizable and shared signal database

Advanced RF analysis where ever you go

- Full-featured spectrum and signal analyzer up to 7.5GHz with a tracking generator

- 40 MHz acquisition bandwidth

- +30 dBm to -162 dBm measurement range

- Free SignalVu-PC VSA Software with 17 free measurements including spectrogram

CONCLUSION

The Internet of Things is more than just a buzzword. It is an opportunity to create additional customer value through smart devices and analytics. To some teams building IoT devices, hardware is just the beginning. At Tektronix, we believe that hardware is the foundation upon which you build software and analytics capabilities. Overcoming the challenges presented in this eBook allows you to build that foundation to make Internet of Things even more resilient.

In this book, we've given a general overview of the six key challenges facing device makers when building devices with wireless communications and/or battery operation.More information on these topics can be found at tektronix.com/IoT, where you will find technical tutorials about each challenge. Articles, webinars, videos, blogs, and much more can be found at tektronix.com to support all of your electronic ventures.

Putting together an IoT ready test suite does not need to be expensive or difficult.Tektronix's offerings, which include instruments, software, and service, can cover all of your needs while still presenting tremendous value. To learn more about our solutions, access more educational resources, get in touch with one of our expert or request a quote, please visit tektronix.com. We are looking forward to partnering with you.

Find more valuable resources at TEK.COM

Copyright © Tektronix. All rights reserved. Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all previously published material. Specification and price change privileges reserved. TEKTRONIX and TEK are registered trademarks of Tektronix, Inc. All other trade names referenced are the service marks, trademarks or registered trademarks of their respective companies.

03/17 37W-60226-2